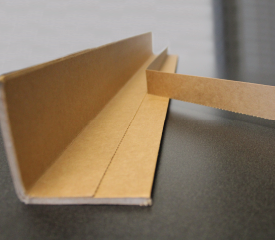

Products – Corner Board Perforation Placement System (CPPS™)

N.A.L. Company® customers have been asking us to produce a corner board in which their packaging personnel would not have to constantly hold the various lengths of corner board to the corner of the product while they are packaging it together. Months of research for this case study and development were spent on adhesive backed corner boards; auto feed tape machines, and visiting different plants to help design a product for their application. The end goal was to devise a product which produces little scrap, occupies very little time and is cost effective while reducing potential safety or ergonomic hazards.

Corner Board Perforation Placement System (CPPS™) was developed, adopted and patented May 1, 2009 BY N.A.L. Company®

United State Dept. Patent and Trademark Office application #61/217.814

This process provides not only a reduction in time, tape or adhesive but also acts as a safety function. By applying CPPS™ to each corner of the products you are protecting, the final package can then be stretch wrapped or packaged without an individual personally holding each corner board on all corners while inside the safety zone of a banding machine or a packaging machine. By creating the Corner Board Perforation Placement System (CPPS™), we have created a product which is very useful in the manufacturing and packaging industries. Before CPPS™, expensive tapes, adhesives and methods were used to apply the corner board to the sides, tops or bottoms of items to protect them from damage during stacking for storage or while in transit by truck or forklift.